Multiply Labs uses robotics and NVIDIA simulation to scale cell therapy manufacturing

The San Francisco-based company says automation can cut cell therapy costs by more than 70% while dramatically increasing production capacity.

San Francisco-based Multiply Labs is automating the manufacture of gene-modified cell therapies using robotic systems trained in advanced simulation environments developed by NVIDIA.

Founded in 2016, Multiply Labs supplies end-to-end robotic manufacturing systems designed to produce personalised cell therapies at industrial scale. The company said its customers include Kyverna Therapeutics and Legend Biotech, both of which are developing advanced gene-modified therapies.

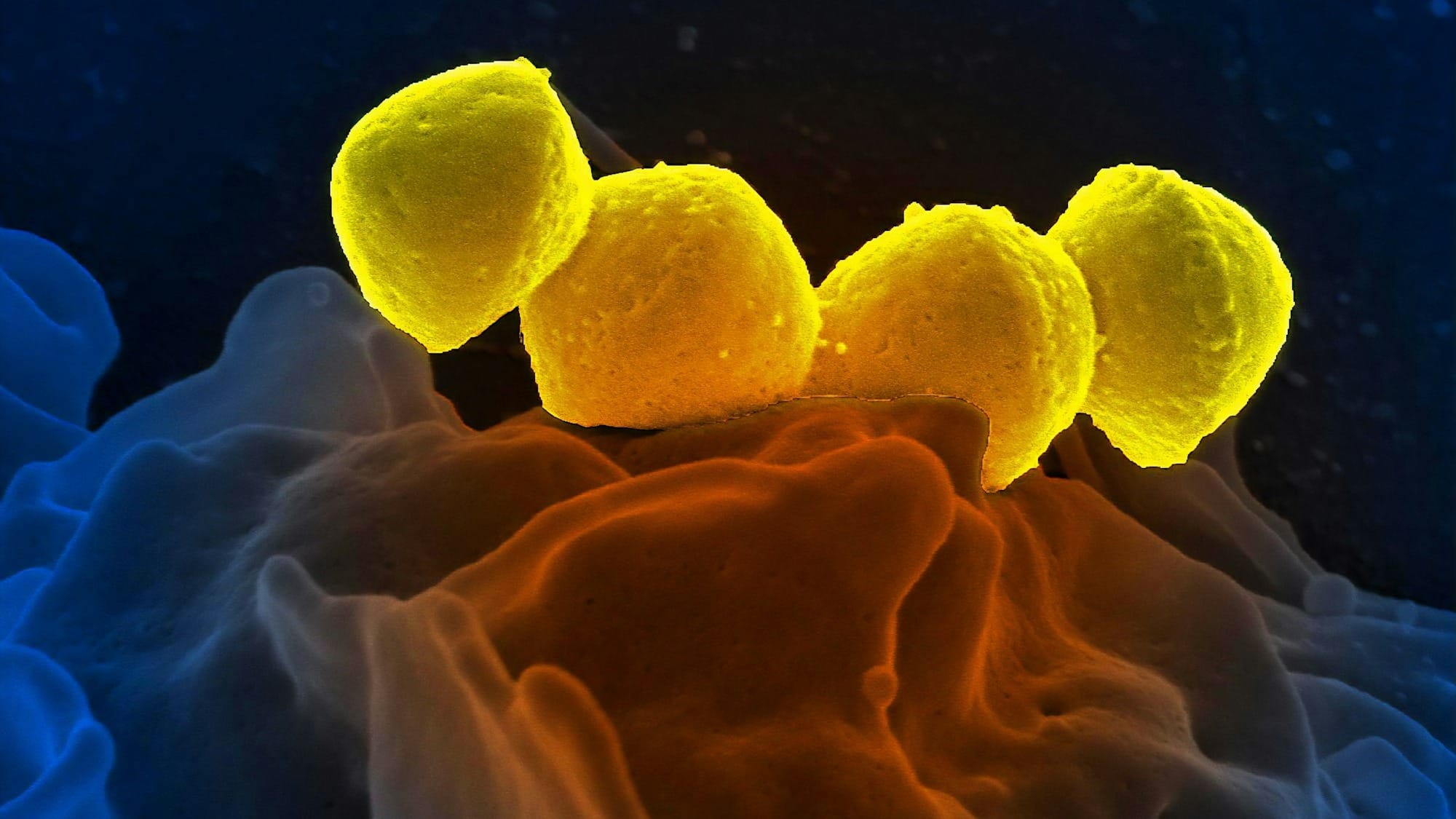

Cell therapies, such as CAR-T treatments, are among the most complex and expensive medicines to manufacture. Production often involves highly manual, bespoke laboratory processes carried out in sterile environments by skilled scientists. Multiply Labs said those constraints have limited throughput and kept costs high, with manufacturing expenses often exceeding $100,000 per dose.

The company is addressing that challenge by translating expert laboratory work into robotic processes. It uses NVIDIA Omniverse to create digital twins of manufacturing environments, allowing systems to be designed, tested and optimised virtually before deployment. Robots are then trained in simulation using NVIDIA Isaac Sim, reducing the time and risk associated with real-world experimentation.

Rather than relying on hand-coded instructions, Multiply Labs uses imitation learning to train robots directly from video demonstrations of expert scientists performing tasks. NVIDIA models such as FoundationPose and FoundationStereo are used to extract precise trajectories from video footage and convert them into robotic control policies.

Fred Parietti, co-founder and chief executive of Multiply Labs, said the approach allows robots to replicate human expertise with high fidelity. “We’re literally training the robot on the exact video example of the best scientist, and we prove that they are statistically equivalent,” he said.

According to the company, automation delivers both economic and spatial efficiency. Multiply Labs said manufacturing costs can be reduced by more than 70%, bringing per-dose costs down to around $25,000 to $35,000. At the same time, robotic systems can increase output by as much as 100 times per square foot compared with traditional clean-room manufacturing.

That combination is intended to shift cell therapies from niche, small-batch production to scalable industrial processes. Multiply Labs argues that without such changes, many promising therapies will remain inaccessible to large patient populations due to cost and capacity constraints.

Beyond fixed robotic cells, the company is also developing humanoid robotic assistants to operate outside controlled manufacturing clusters. These systems are being built using the NVIDIA Isaac GR00T foundation model and are designed to handle tasks such as loading and unloading materials, further reducing reliance on manual labour in sensitive environments.

Parietti said the broader goal is to democratise access to advanced therapies. “We want to enable the shift of the industry from niche to scale, 100 times more therapies at 70% less cost, so life-saving treatments aren’t just for the few, but for the millions,” he said.

As demand for personalised medicines grows, Multiply Labs’ approach highlights how robotics, simulation and artificial intelligence are beginning to reshape biomanufacturing, turning highly specialised laboratory work into repeatable, scalable industrial processes.

The Recap

- Multiply Labs deploys robotics to automate cell therapy manufacturing.

- Company says robots cut dose cost more than 70%.

- Systems use NVIDIA Omniverse, Isaac Sim and Isaac GR00T.